Kayayyaki

Module Ma'aunin MEMS M13 - Madaidaicin Ma'auni don Babban Ayyuka

Iyakar aikace-aikace

● ɗan gajeren lokacin farawa.

● Tacewar dijital da algorithms ramuwa don firikwensin.

● Ƙananan ƙararrawa, ƙananan amfani da wutar lantarki, nauyi mai sauƙi, sauƙi mai sauƙi, sauƙi don shigarwa da amfani.

Filin Aikace-aikace

● Mai horar da XX

● Dandalin daidaitawa na gani

Ma'aunin Ayyukan Samfur

| samfurSamfura | MEMSHaliModule | ||||

| SamfuraSamfura | Saukewa: XC-AHRS-M13 | ||||

| Nau'in awo | Sunan awo | Ma'aunin Aiki | Jawabi | ||

| Daidaiton Hali | hanya | 1 ° (RMS) | |||

| Fita | 0.5°(RMS) | ||||

| Mirgine | 0.5°(RMS) | ||||

| gyroscope | Rage | ± 500°/s | |||

| Cikakken ma'aunin ma'aunin zafin jiki ba shi da tushe | ≤200ppm | ||||

| Haɗin kai | ≤1000ppm | ||||

| Biased (cikakken zafin jiki) | ≤±0.02°/s | (Hanyar tantance ma'aunin soja ta ƙasa) | |||

| Kwanciyar hankali | ≤5°/h | (1σ, 10s santsi, cikakken zafin jiki) | |||

| Maimaituwar rashin son zuciya | ≤5°/h | (1 σ, cikakken zafin jiki) | |||

| Bandwidth (-3dB) | ? 200 Hz | ||||

| accelerometer | Rage | ± 30g | Matsakaicin ± 50g | ||

| Haɗin kai | ≤1000ppm | ||||

| Biased (cikakken zafin jiki) | ≤2mg | Cikakken zafin jiki | |||

| Kwanciyar hankali | ≤0.2mg | (1σ, 10s santsi, cikakken zafin jiki) | |||

| Maimaituwar rashin son zuciya | ≤0.2mg | (1 σ, cikakken zafin jiki) | |||

| Bandwidth (-3dB) | ? 100 Hz | ||||

| InterfaceCharacteristics | |||||

| Nau'in mu'amala | Saukewa: RS-422 | Baud darajar | 38400bps (mai iya canzawa) | ||

| Tsarin Bayanai | 8 Data bit, 1 farawa bit, 1 tasha bit, babu shiri mara shiri | ||||

| Adadin sabunta bayanai | 50Hz (na iya canzawa) | ||||

| MuhalliAdaptability | |||||

| Yanayin zafin aiki | -40℃~+75℃ | ||||

| Ma'ajiyar zafin jiki | -55℃~+85℃ | ||||

| Jijjiga (g) | 6.06gms, 20Hz ~ 2000Hz | ||||

| LantarkiCharacteristics | |||||

| Input irin ƙarfin lantarki (DC) | + 5VC | ||||

| Na zahiriCharacteristics | |||||

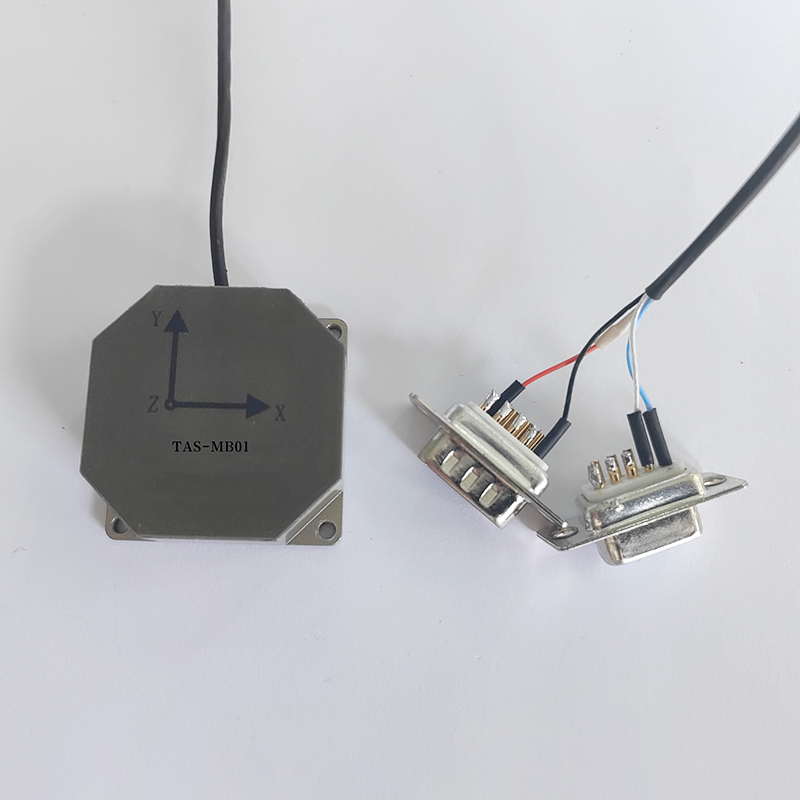

| Girman | 56mm × 48mm × 29mm | ||||

| Nauyi | ≤120g | ||||

Gabatarwar Samfur

An sanye shi da sabuwar fasahar MEMS, tsarin kayan aikin M13 MEMS yana da matukar kulawa, daidai kuma daidai. An yi niyya ne don amfani da tsarin a cikin aikace-aikace da yawa da suka haɗa da sararin samaniya, injiniyoyin mutum-mutumi, ruwa da masana'antar kera motoci. Tare da ma'auni na ainihin lokaci da algorithms masu ci gaba, M13 MEMS kayan aiki na kayan aiki na iya gano canje-canje a cikin matsayi na mai ɗauka nan take, yana samar da babban matakin daidaito da hankali.

Ɗayan mahimman fasalulluka na ƙirar kayan aikin M13 MEMS shine ƙaramin girmansa. Ƙaƙƙarfan ƙaƙƙarfan tsarin ƙirar, ƙirar ƙira yana tabbatar da cewa ana iya haɗa shi ba tare da matsala ba cikin kowane tsari ko aikace-aikace. Har ila yau, tsarin yana da ƙarancin amfani da wutar lantarki, yana mai da shi manufa don amfani da shi a cikin kayan aiki mai ɗaukar hoto ko mai sarrafa baturi. Ƙarƙashin wutar lantarki na tsarin yana nufin za'a iya amfani dashi na tsawon lokaci ba tare da yawan canjin baturi ba ko yin caji don matsakaicin dacewa.

Bugu da ƙari, M13 MEMS Gauge Module yana da kyakkyawan aminci, yana tabbatar da cewa za'a iya amfani da samfurin a kowane yanayi mai tsanani kuma yana iya tsayayya da yanayin muhalli kamar zazzabi, zafi da girgiza. Na'urar tana da matuƙar ɗorewa kuma tana da ƙarfi, tana ba da ingantaccen bayanan ma'auni ko da a ƙarƙashin mafi ƙalubale yanayi.

M13 MEMS kayan aikin kayan aiki an tsara su don saduwa da buƙatun aikace-aikace da masana'antu iri-iri. Tare da madaidaicin ma'aunin sa, ƙirar tana da kyau don amfani a cikin masana'antar sararin samaniya, inda ma'auni daidai suke da mahimmanci don sarrafa jirgin da tsarin kewayawa. Hakanan samfurin ya dace da tsarin tsaro na ci gaba a cikin masana'antar kera motoci, kamar hana birki, sarrafa kwanciyar hankali da gano karo. A lokaci guda, ana iya amfani da na'urar kayan aikin mM13 MEMS a cikin masana'antar ruwa don samar da ma'auni masu aminci don kewayawa.

- Girma da Tsarin Za'a Iya Keɓancewa

- Alamomi sun Rufe Gabaɗayan Rage daga ƙasa zuwa babba

- Matsakaicin Ƙananan Farashi

- Shortan Lokacin Isarwa da Saƙon da Ya dace

- Binciken Haɗin gwiwar Makaranta-Kasuwanci Haɓaka Tsarin

- Mallakar Faci Na atomatik da Layin Taro

- Nasu dakin gwaje-gwajen Matsalolin Muhalli